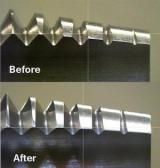

The proper edge preparation for taps is different from other cutting tools. There are multiple cutting geometries on the end of a tap and two common methods for edge preparation are vapor honing and abrasive blasting or immersion. Regal uses a method that is closely controlled to ensure consistency. Doing this necessitates the use of a variety of grain sizes and composition, along with a rotating speed dependent on tool diameter. For example, a #4-40 tap requires a completely different process than a ¾-10.

After thorough investigation, Regal’s engineers selected the precise process suitable for the intricate cutting angles of thread forms, a Micro Finish Edge Preparation process. It is applied to all taps up to one inch in diameter.

This process does two important things.

All Regal taps 1” and under go through the Micro Finish Edge Preparation process. Our coated taps go through the Micro-Finish process not once, but twice! Once before coating and again after the coating process is completed. By paying close attention to detail over these final steps, we ensure our customers the finest taps and extended tool life.