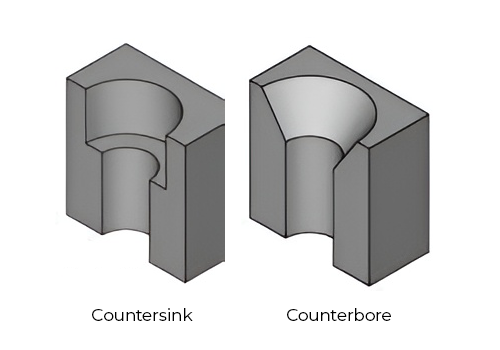

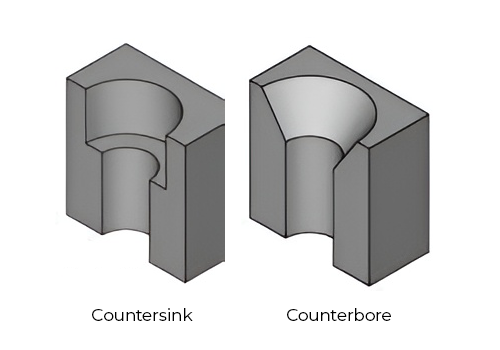

When Do I Need To Countersink or Counterbore A Hole and Which Should I Use?

Don’t split your surface! Here’s all you need to know to countersink (or counterbore) before you screw it up.

The manufacture of fasteners is segmented by standard fasteners and specialty fasteners.

Standard fasteners are made on high volume, high speed unique machines designed for optimum productivity. Unlike most tapping, the tool does not retract, but rather the nuts continue on the shank and are dropped into a container. Nutap, Sakai and Nomura are dominant machines used to produce nuts in this fashion.

Regal supplies brazed and threaded shank taps for these applications. Print specifications are required due to variables in the tapping conditions.

Specialty fasteners for the aircraft industry are normally made from stainless steel or more exotic materials. Taps we design for these parts are made from high alloy particle metal with specific geometry for producing high quality threads.

Large diameter nuts and other fastening devices, because of small quantities, frequently are tapped on conventional machines, where accurate fit and finish can be attained.

Regal supplies custom special taps and blueprint specification (often with special lengths or features). Using the right tap can optimize performance and extend the life of the tap itself. Large diameter taps conforming to standard tolerances produce excellent results under normal conditions.

See our product solutions below, or contact us to talk to our experienced customer service representatives who can help determine the best design for your needs.

Standard fasteners are made on high volume, high speed machines designed for optimum productivity. Unlike most tapping, the tool does not retract, but rather the nuts continue on the shank and are dropped into a container. Specialty fasteners for the aircraft industry are normally made from stainless steel or more exotic materials. Taps we design for these parts are made from high alloy particle metal with specific geometry for producing high quality threads. Large diameter nuts and other fastening devices, because of small quantities, frequently are tapped on conventional machines, where accurate fit and finish can be attained.

Maintain a sharp cutting edge, run at higher speed rates, and absorb heat more efficiently.

This flute design helps in efficient chip evacuation during the tapping process.

Regal supplies custom special taps and blueprint specification (often with special lengths or features). Using the right tap can optimize performance and extend the life of the tap itself. Large diameter taps conforming to standard tolerances produce excellent results under normal conditions.

Regal supplies brazed and threaded shank taps for these applications. Print specifications are required due to variables in the tapping conditions.

Don’t split your surface! Here’s all you need to know to countersink (or counterbore) before you screw it up.

Regal has created imperial and metric tap drill charts to help users tap holes with sufficient thread % while maximizing tap life. Learn more about choosing the optimal tap drill!

From playground equipment to blades on a wind turbine, nuts hold everything together. Learn how Regal Cutting Tools serves fastener manufacturers to help keep everything held together.

When you need to thread a hole, it may seem easiest to reach for the nearest right-size tap. But even before drilling the hole, professional machinists consider the material being tapped, whether the hole is through or blind, and other variables before deciding whether to use a cut tap or a form tap.