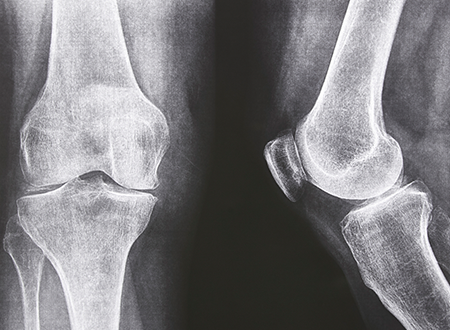

Over recent years, there has been a dramatic expansion in the way that joints in the human body can be replaced if needed. For a number of years, this was usually done by use of human body parts. However, with rise of demand and technological advances this has changed in recent history.

Today, replacement joints are commonly made using titanium or other high alloy materials. Only specialized companies are involved in this delicate and important process, and they use the most advanced CNC tools for their machines.

There has been a frequent, almost annual, changeover for the modelling and remodeling of the medical diagnostic tools in the recent past. This is due to the drastic improvements in the equipment and a frequent change in safety issues. All of this equipment is brought to life through the use of taps, end mills, drills and gages of different sizes.

The SuperTuf line from Regal Cutting Tools consists of center-cutting standard, high, and variable helix end mills including special-dimension end mills that meet all of the toughest requirements. In the medical industry, carbide end mills are the tool of choice. Regal provides these end mills in both multi-purpose and high performance configurations. Premium end mills are also very productive and cost-efficient when it comes to applications in deep contouring.

Regal produces a complete line of end mills that are manufactured using ultra micro-grain carbide. This not only ensures hardness, but provides a long tool life.

Depending on the job’s requirements, you can choose the most suitable end mill from our list of high performance end mills:

Regal Cutting Tools is proud to be part of the production of replacement joints so that people can regain their mobility. Click here for more information on Regal’s involvement and what products best suit the medical industry.