SuperTuf Material Specific Taps: Extend Tool Life & Increase Profitability

Aerospace, fluid power, and other manufacturing industries continue to develop and rely on alloys with the exact properties they need to deliver optimum performance. Learn about Regal’s SuperTuf Coating that these industries use to get the job done.

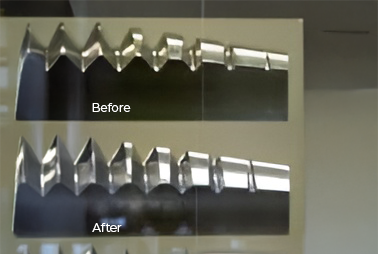

Multi-Finish Micro Edge Preparation Process: Why Regal Does it, and Why We Do It For Free

Regal’s current tap preperation method increases tool life, produces a smoother finish and creates the ideal surface condition prior to coating for no additional coating.

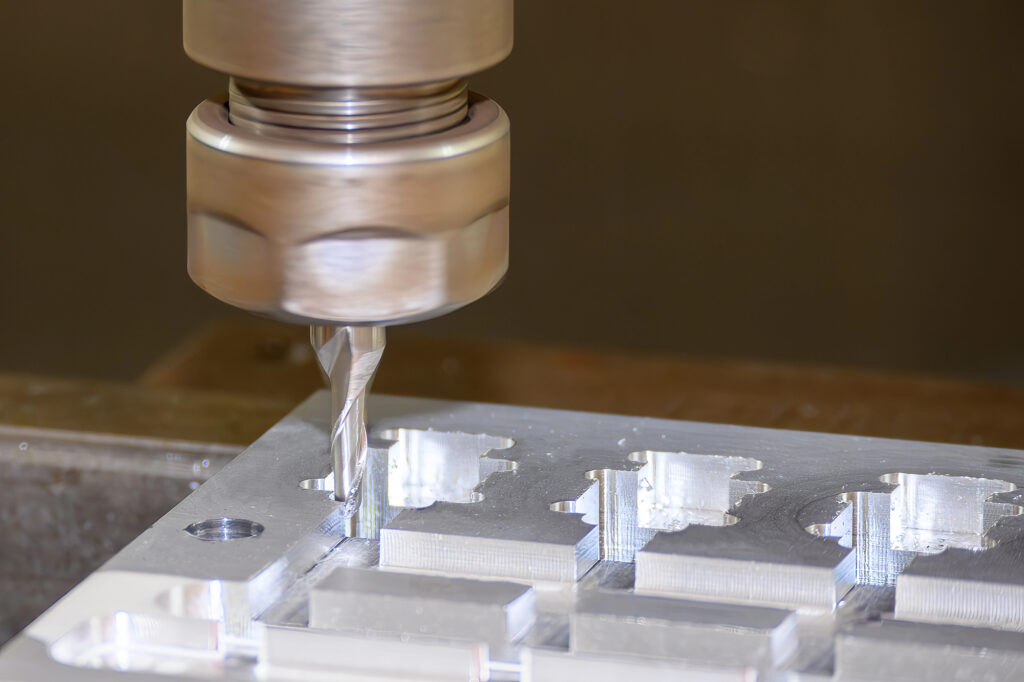

End Milling Aluminum Using the Right Tools

Too often when machining aluminum, the assumption made is that any tool will do because aluminum is easy to cut. Learn why this isn’t always the case.

Regal Cutting Tools Employees Mentor Beloit Memorial High School Tech Ed Industrial Arts Students

Regal Cutting Tools is proud to help area students learn the valuable skills necessary to succeed in the modern day manufacturing environment.

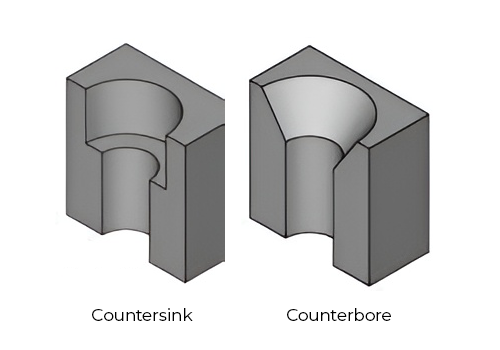

When Do I Need To Countersink or Counterbore A Hole and Which Should I Use?

Don’t split your surface! Here’s all you need to know to countersink (or counterbore) before you screw it up.

4 Tips That Will Extend End Mill Life

Want to increase your tool life? Check out these 4 tips that will help extend the life of your end mills!

How to Select the Optimal Tap for Desired Results

Unsure of what tap is best for your next job? Use this informative article to take the guesswork out of your decision.

S & D Drills for Portable and Drill Press Operations

Learn about the history behind Silver & Deming Drills and Regal’s offering of these drills!

Production Drilling with Carbide Offers Choices that Affect the Bottom Line

When drilling reasonably close tolerance holes in materials conducive to using solid carbide drills, you have some choices.

Tap Selection for Plated Internal Threads

Avoid failed inspections, customer rejection, and lost profits by following these tap selection tips.